Dominion Atlantic Railway Digital Preservation Initiative - Wiki

Use of this site is subject to our Terms & Conditions.

Difference between revisions of "Berwick Evaporator"

Dan conlin (talk | contribs) (jmage) |

Dan Conlin (talk | contribs) (demolition date with footnote) |

||

| (7 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

__NOTITLE__ | __NOTITLE__ | ||

__NOTOC__ | __NOTOC__ | ||

| − | ==[[Berwick]] | + | ==[[Berwick]] Evaporator== |

| − | [[File: | + | [[File:Evaporator1919.png|thumb|400px|[[Berwick Evaporator]] and spur line, circa 1919]] |

| − | + | [[Berwick]]’s evaporator was one of the biggest on the DAR. Evaporators produced dried apple slices, often used as supplies for isolated lumber and construction camps. Evaporator plants provided an important market for small or damaged apples that were unsuitable for the fresh export market and the plants were the forerunner of later fruit processing plants. The Berwick evaporator was established in 1917 by Robert J. Graham, an ambitious businessman from Belleville, Ontario,<ref>Dan Conlin, "Evaporating Apple History", [[Kings County Register August 3, 2006|''Kings County Register'', August 3, 2006, p.7]]</ref> who saw an opportunity in the demand for dehydrated military rations in the First World War. He bought out and built evaporators across the valley, including the evaporators in [[Windsor]], [[Waterville]], [[Lakeville]] and [[Bridgetown]].<ref>"Berwick to Have Big Evaporator", ''The Acadian'', May 25 1917. Courtesy Phil Vogler</ref> In Berwick he built a large factory, complete with its own adjacent fruit warehouse and railway spur line. | |

| + | |||

| + | The Berwick Evaporator was constructed by [[J. H. Hicks & Sons]] of [[Bridgetown]].<ref>''The Weekly Monitor'', May 23, 1917, courtesy Phil Vogler</ref> for a cost of $12,000. Construction began on May 18, 1917.<ref>"Berwick to Have Big Evaporator", ''The Acadian'', May 25 1917. Courtesy Phil Vogler</ref> The evaporator was large two-story building, later expanded to three and a half stories, surrounded by a large loading bay to receive apples and load the finished product onto boxcars. A thousand foot spur from the mainline to held up to 17 boxcars. A lane built to construct and service the evaporator became Berwick's Front Street. Inside the building, apples were pared and sliced by machinery powered by a coal fired boiler and its 80 foot iron smokestack. Roaring fires in six furnaces dried sliced apples in special tin-lined kilns, sending the water steaming out through the evaporator's characteristic roof vents. The evaporator was a seasonal opertion which started with the apple crop in September and ran 11 hours a day, six days a week, until spring when the apples supply ran out.<ref>Dan Conlin, "Evaporating Apple History", [[Kings County Register August 3, 2006|''Kings County Register'', August 3, 2006, p.7]]</ref> It employed a large, mostly female workforce, employing up to 75 women when it began. Evaporated apples were the main product, but it was also constructed to process evaporated potatoes and can other fruit and vegetables.<ref>"Berwick to Have Big Evaporator", ''The Acadian'', May 25 1917. Courtesy Phil Vogler</ref> | ||

| + | |||

| + | Graham overextended himself in the valley and soon ran into trouble. According to a "History of Berwick Apple Warehouses" an article written by Robert Chute, the Berwick evaporator stood idle for long periods as Graham was forced to sell off his valley plants. In 1933, the Simms Company of Saint John, New Brunswick bought the Graham properties. The Simms ran most seasons, but would suspend operations if the supply of culled apples was small or the price was high. The evaporator assumed an even more important role in World War Two. Wartime shipping restrictions cut off the Valley from Britain, its biggest market. Evaporators, along with juice factories were one of the few remaining customers for the bulk of the valley crop as they produced large volumes of apple by-products as wartime rations.<ref>Dan Conlin, "Evaporating Apple History", [[Kings County Register August 3, 2006|''Kings County Register'', August 3, 2006, p.7]]</ref> | ||

| + | |||

| + | During the war, Simms sold the evaporator to R.A. Parker and Sons. In 1945, the [[:Category:United Fruit Companies|United Fruit Companies]] briefly owned the evaporator plant before selling it to Roy Jodrey of Hantsport. The valley's apple industry never regained its former glory after the wartime loss of the British market and the Jodreys switched the plant to canning pears as part of their Avon Foods chain of plants along the DAR. | ||

| + | |||

| + | Eventually the pear operation was closed down and the old evaporator stood silent for a number of years until it purchased by John Palmer of Morristown. It was finally demolished by H.E. Margeson in November 1974 beginning with the 80 foot smokestack which was toppled on November 4, 1974.<ref>"Old Landmark Coming Down", ''The Register'' November 6, 1974, courtesy [[:Category:Phill Vogler|Phil Vogler and Betty Smith</ref> The site is now used for parking and building materials by the Berwick Home Hardware. The evaporator was recreated on a railway diorama made by volunteers at the [[:Category:Apple Capital Museum|Berwick Apple Capital Museum]] in 2007, represented by an HO model made by Dan Conlin.<ref>Dan Conlin, "Evaporating Apple History", [[Kings County Register August 3, 2006|''Kings County Register'', August 3, 2006, p.7]]</ref> | ||

==Gallery== | ==Gallery== | ||

<Gallery> | <Gallery> | ||

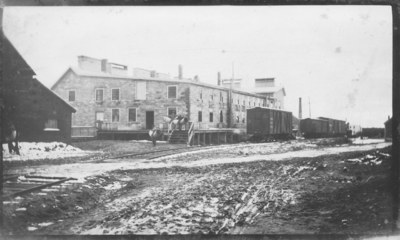

| − | File: | + | File:Evaporator1919.png|[[Berwick Evaporator]] soon after construction with spur, boxcars and other buildings on Front Street, circa 1919. |

| − | File: | + | File:Evapcalendar.jpg|[[Berwick Evaporator]] calendar for 1920 with photo of the evaporator soon after construction in 1919. |

| − | + | Image:Berwick Railyard.JPG|[[Berwick]] railyard, evaporator, warehouse and [[Berwick Station|station]], May 1931. | |

| − | File: | + | File:Berwick1931.jpg|Berwick looking south, 1931, showing east end of Berwick Evaporator. |

| − | Image:1938 Berwick insurance map.JPG|Berwick Fire Insurance Map, showing | + | Image:1938 Berwick insurance map.JPG|Berwick Fire Insurance Map, showing evaporator, 1938. |

| − | + | Image:Evap model medres.JPG|Model of Berwick Evaporator at the [[:Category:Apple Capital Museum|Apple Capital Museum]] by Dan Conlin, 2008. | |

| − | + | Image:Evp Detail medres.JPG|Detail of evaporator model at the [[:Category:Apple Capital Museum|Apple Capital Museum]] showing loading dock, 2008. | |

| + | File:Kings County Register August 3, 2006 .jpg|Article about the Berwick Evaporator, 2006. | ||

| + | |||

</Gallery> | </Gallery> | ||

==References and Footnotes== | ==References and Footnotes== | ||

| + | *''[[Some Economic Aspects of the Apple Industry in Nova Scotia]]'' by Willard Longley | ||

*''Valley Gold'' by Ann Hutton | *''Valley Gold'' by Ann Hutton | ||

<references /> | <references /> | ||

Latest revision as of 16:12, 2 April 2025

Berwick Evaporator

Berwick’s evaporator was one of the biggest on the DAR. Evaporators produced dried apple slices, often used as supplies for isolated lumber and construction camps. Evaporator plants provided an important market for small or damaged apples that were unsuitable for the fresh export market and the plants were the forerunner of later fruit processing plants. The Berwick evaporator was established in 1917 by Robert J. Graham, an ambitious businessman from Belleville, Ontario,[1] who saw an opportunity in the demand for dehydrated military rations in the First World War. He bought out and built evaporators across the valley, including the evaporators in Windsor, Waterville, Lakeville and Bridgetown.[2] In Berwick he built a large factory, complete with its own adjacent fruit warehouse and railway spur line.

The Berwick Evaporator was constructed by J. H. Hicks & Sons of Bridgetown.[3] for a cost of $12,000. Construction began on May 18, 1917.[4] The evaporator was large two-story building, later expanded to three and a half stories, surrounded by a large loading bay to receive apples and load the finished product onto boxcars. A thousand foot spur from the mainline to held up to 17 boxcars. A lane built to construct and service the evaporator became Berwick's Front Street. Inside the building, apples were pared and sliced by machinery powered by a coal fired boiler and its 80 foot iron smokestack. Roaring fires in six furnaces dried sliced apples in special tin-lined kilns, sending the water steaming out through the evaporator's characteristic roof vents. The evaporator was a seasonal opertion which started with the apple crop in September and ran 11 hours a day, six days a week, until spring when the apples supply ran out.[5] It employed a large, mostly female workforce, employing up to 75 women when it began. Evaporated apples were the main product, but it was also constructed to process evaporated potatoes and can other fruit and vegetables.[6]

Graham overextended himself in the valley and soon ran into trouble. According to a "History of Berwick Apple Warehouses" an article written by Robert Chute, the Berwick evaporator stood idle for long periods as Graham was forced to sell off his valley plants. In 1933, the Simms Company of Saint John, New Brunswick bought the Graham properties. The Simms ran most seasons, but would suspend operations if the supply of culled apples was small or the price was high. The evaporator assumed an even more important role in World War Two. Wartime shipping restrictions cut off the Valley from Britain, its biggest market. Evaporators, along with juice factories were one of the few remaining customers for the bulk of the valley crop as they produced large volumes of apple by-products as wartime rations.[7]

During the war, Simms sold the evaporator to R.A. Parker and Sons. In 1945, the United Fruit Companies briefly owned the evaporator plant before selling it to Roy Jodrey of Hantsport. The valley's apple industry never regained its former glory after the wartime loss of the British market and the Jodreys switched the plant to canning pears as part of their Avon Foods chain of plants along the DAR.

Eventually the pear operation was closed down and the old evaporator stood silent for a number of years until it purchased by John Palmer of Morristown. It was finally demolished by H.E. Margeson in November 1974 beginning with the 80 foot smokestack which was toppled on November 4, 1974.[8] The site is now used for parking and building materials by the Berwick Home Hardware. The evaporator was recreated on a railway diorama made by volunteers at the Berwick Apple Capital Museum in 2007, represented by an HO model made by Dan Conlin.[9]

Gallery

Berwick Evaporator soon after construction with spur, boxcars and other buildings on Front Street, circa 1919.

Berwick Evaporator calendar for 1920 with photo of the evaporator soon after construction in 1919.

Model of Berwick Evaporator at the Apple Capital Museum by Dan Conlin, 2008.

Detail of evaporator model at the Apple Capital Museum showing loading dock, 2008.

References and Footnotes

- Some Economic Aspects of the Apple Industry in Nova Scotia by Willard Longley

- Valley Gold by Ann Hutton

- ↑ Dan Conlin, "Evaporating Apple History", Kings County Register, August 3, 2006, p.7

- ↑ "Berwick to Have Big Evaporator", The Acadian, May 25 1917. Courtesy Phil Vogler

- ↑ The Weekly Monitor, May 23, 1917, courtesy Phil Vogler

- ↑ "Berwick to Have Big Evaporator", The Acadian, May 25 1917. Courtesy Phil Vogler

- ↑ Dan Conlin, "Evaporating Apple History", Kings County Register, August 3, 2006, p.7

- ↑ "Berwick to Have Big Evaporator", The Acadian, May 25 1917. Courtesy Phil Vogler

- ↑ Dan Conlin, "Evaporating Apple History", Kings County Register, August 3, 2006, p.7

- ↑ "Old Landmark Coming Down", The Register November 6, 1974, courtesy [[:Category:Phill Vogler|Phil Vogler and Betty Smith

- ↑ Dan Conlin, "Evaporating Apple History", Kings County Register, August 3, 2006, p.7