Dominion Atlantic Railway Digital Preservation Initiative - Wiki

Use of this site is subject to our Terms & Conditions.

Difference between revisions of "Apple Trains"

Dan conlin (talk | contribs) (→Rolling Stock: image) |

Dan conlin (talk | contribs) (→Apple Trains: reefers to New York) |

||

| Line 3: | Line 3: | ||

==Apple Trains== | ==Apple Trains== | ||

| − | Apple freight was the DAR's most important cargo. Apple traffic helped build the DAR and the DAR built the Valley's apple industry from a small side-crop to a major international export. Apple traffic averaged between 1 and 2 million barrels a year with the record crop in 1933 hitting 3,673,678 barrels.(3) Britain was the world's largest importer of apples and in the 1930s, one out of every ten apples sold in Britain came from from Annapolis Valley farms via the DAR. Over 150 [[:Category:Apple Warehouses|apple warehouses]] lined the route of the DAR.(2) However, the loss of the British export market during World War Two crippled the apple industry and greatly reduced DAR freight traffic from the 1940s onward. The hundreds of apple warehouses closed, although the surviving volume of apple traffic processed at centralized apple processing plants such as [[Scotian Gold]] at [[Coldbrook]], [[M. W. Graves]] in [[Berwick]] and the [[Canada Foods Plant]] in [[Kentville]] remained important DAR customers in later years. | + | Apple freight was the DAR's most important cargo. Apple traffic helped build the DAR and the DAR built the Valley's apple industry from a small side-crop to a major international export. Apple traffic averaged between 1 and 2 million barrels a year with the record crop in 1933 hitting 3,673,678 barrels.(3) Britain was the world's largest importer of apples and in the 1930s, one out of every ten apples sold in Britain came from from Annapolis Valley farms via the DAR. Over 150 [[:Category:Apple Warehouses|apple warehouses]] lined the route of the DAR.(2) However, the loss of the British export market during World War Two crippled the apple industry and greatly reduced DAR freight traffic from the 1940s onward. Valley farmers had to shift from a massive overseas export market of fresh fruit to a smaller national and regional market, with a few exports to the competitive apple market in the United States.<ref>Email from George Melvin, Maine, via [[Bill Linley]] (31 May 2020) noting that apples were shipped from the Annapolis Valley to processors in upstate NY in reefers of the Rutland Ogdensburg Line in the early 1950s.</ref> Focus moved more on processed apple products such as juice. The hundreds of apple warehouses closed, although the surviving volume of apple traffic processed at centralized apple processing plants such as [[Scotian Gold]] at [[Coldbrook]], [[M. W. Graves]] in [[Berwick]] and the [[Canada Foods Plant]] in [[Kentville]] remained important DAR customers in later years. |

===Operations=== | ===Operations=== | ||

| Line 10: | Line 10: | ||

===Rolling Stock=== | ===Rolling Stock=== | ||

[[File:Armstrong2501.jpg|thumb|left|200px|[[:Category:Refrigerator Cars|Refrigerator car]] custom-built for DAR apple service, circa 1905.]] | [[File:Armstrong2501.jpg|thumb|left|200px|[[:Category:Refrigerator Cars|Refrigerator car]] custom-built for DAR apple service, circa 1905.]] | ||

| − | The DAR used standard 36 and 40 foot boxcars in summer and early fall. In early years, ventilated boxcars were popular for early fall shipments to avoid heat and moisture build-up. During the winter when freezing temperatures arrived, a large fleet of specially adapted insulated boxcars were used for apple service, the [[DAR069938|69900 series]]. Portable stoves were often carried in the box cars in winter to avoid freezing, tended by men from apple warehouses who road with the car to Halifax. [[Refrigerator Cars]] also played an important role in winter. Their insulated sides kept apple barrels from freezing in sub-zero temperatures, assisted in very cold weather with portable stoves or charcoal heaters. While refrigerated cars protected apples and ensured a better quality product, the reefers also has less capacity, due to the thick walls and bunkers, with capacity for only 200 barrels of apples as opposed to 300 barrels in a standard boxcar.<ref>Anne Hutton, ''Valley Gold'', Halifax: Petheric Press (1981) p. 83</ref> | + | The DAR used standard 36 and 40 foot boxcars in summer and early fall. In early years, ventilated boxcars were popular for early fall shipments to avoid heat and moisture build-up. During the winter when freezing temperatures arrived, a large fleet of specially adapted insulated boxcars were used for apple service, the [[DAR069938|69900 series]]. Portable stoves were often carried in the box cars in winter to avoid freezing, tended by men from apple warehouses who road with the car to Halifax. This method counted on carefully timed shipments that left the valley in the morning to be loaded on the British-bound steamships the same day to minimize the risk cold weather damage in transit. [[Refrigerator Cars]] also played an important role in winter. Their insulated sides kept apple barrels from freezing in sub-zero temperatures, assisted in very cold weather with portable stoves or charcoal heaters. While refrigerated cars protected apples and ensured a better quality product, the reefers also has less capacity, due to the thick walls and bunkers, with capacity for only 200 barrels of apples as opposed to 300 barrels in a standard boxcar.<ref>Anne Hutton, ''Valley Gold'', Halifax: Petheric Press (1981) p. 83</ref> CP refrigerator cars were used to carry some North American export apple traffic, such shipments to processors in Upstate New York in the 1950s.<ref>Email from George Melvin, Maine, via [[Bill Linley]] (31 May 2020) noting that apples were shipped from the Annapolis Valley to processors in upstate NY in reefers of the Rutland Ogdensburg Line in the early 1950s.</ref> |

===Structures=== | ===Structures=== | ||

Revision as of 19:33, 1 June 2020

Apple Trains

Apple freight was the DAR's most important cargo. Apple traffic helped build the DAR and the DAR built the Valley's apple industry from a small side-crop to a major international export. Apple traffic averaged between 1 and 2 million barrels a year with the record crop in 1933 hitting 3,673,678 barrels.(3) Britain was the world's largest importer of apples and in the 1930s, one out of every ten apples sold in Britain came from from Annapolis Valley farms via the DAR. Over 150 apple warehouses lined the route of the DAR.(2) However, the loss of the British export market during World War Two crippled the apple industry and greatly reduced DAR freight traffic from the 1940s onward. Valley farmers had to shift from a massive overseas export market of fresh fruit to a smaller national and regional market, with a few exports to the competitive apple market in the United States.[1] Focus moved more on processed apple products such as juice. The hundreds of apple warehouses closed, although the surviving volume of apple traffic processed at centralized apple processing plants such as Scotian Gold at Coldbrook, M. W. Graves in Berwick and the Canada Foods Plant in Kentville remained important DAR customers in later years.

Operations

From September to April during the peak decades of the apple industry, apples were loaded at 150 apple warehouses along the DAR. Local trains brought them to Kentville to be marshaled into freights bound for steamships in Halifax. In peak seasons, this produced massive double-header 50 boxcar freight specials, as many as six special trains per weekend, requiring an extra switcher locomotive in Kentville and extra CPR vans from Montreal.(1) Apple trains also served the vinegar plants and apple evaporators such the Berwick Evaporator which ran all through the winter. This heavy traffic had to be maintained right through heavy winter snow conditions. In the early years of the W&A, and the DAR, many steamers met trains at Annapolis Royal for apples. The Kingsport Wharf and the Port Williams wharf also served as smaller shipping points for apples. However Halifax grew to be the largest destination for apple trains as it could better serve larger steamers.

Rolling Stock

The DAR used standard 36 and 40 foot boxcars in summer and early fall. In early years, ventilated boxcars were popular for early fall shipments to avoid heat and moisture build-up. During the winter when freezing temperatures arrived, a large fleet of specially adapted insulated boxcars were used for apple service, the 69900 series. Portable stoves were often carried in the box cars in winter to avoid freezing, tended by men from apple warehouses who road with the car to Halifax. This method counted on carefully timed shipments that left the valley in the morning to be loaded on the British-bound steamships the same day to minimize the risk cold weather damage in transit. Refrigerator Cars also played an important role in winter. Their insulated sides kept apple barrels from freezing in sub-zero temperatures, assisted in very cold weather with portable stoves or charcoal heaters. While refrigerated cars protected apples and ensured a better quality product, the reefers also has less capacity, due to the thick walls and bunkers, with capacity for only 200 barrels of apples as opposed to 300 barrels in a standard boxcar.[2] CP refrigerator cars were used to carry some North American export apple traffic, such shipments to processors in Upstate New York in the 1950s.[3]

Structures

See main article Apple Warehouses

Apple warehouses, where apples were packed, stored and shipped, were the centrepoint of apple operations. Evaporators, like the Berwick Evaporator and a dozen others were also important customers for apple trains as well as a few vinegar and cider plants. In later years, large central processing plants like Scotian Gold in Coldbrook and M. W. Graves in Berwick remained important customers.

Berwick Station during the apple export season before apple warehouses were built, 1890s.

The Pleasant Valley apple warehouse during apple shipping season with box car being loaded, with the rear of the Berwick Station to right, 1911.

Apple loading with DAR boxcars No. 1238, 1267 and No. 1300, unknown location, circa 1894 - 1920.

Apple train in Halifax in 1925.

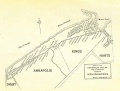

DAR Chart of Apple and Produce Warehouses, February 23, 1927, a map of all apple warehouses on the DAR giving owners and capacity in barrels, 1927.

- CDCDA Apple Warehouse Thumb.jpg

Centreville Station surrounded by apple warehouses.

Apple barrels piled by the station at Centreville.

A double header apple train in Centreville.

Article about the Berwick Apple Evaporator, 2006.

References and Footnotes

(1) Kentville Advertiser, Mar. 25, Sept. 9 and Sept. 16, 1937

(2) Some Economic Aspects of the Apple Industry in Nova Scotia by Willard Longley

(3) Valley Gold by Ann Hutton

External Links

- ↑ Email from George Melvin, Maine, via Bill Linley (31 May 2020) noting that apples were shipped from the Annapolis Valley to processors in upstate NY in reefers of the Rutland Ogdensburg Line in the early 1950s.

- ↑ Anne Hutton, Valley Gold, Halifax: Petheric Press (1981) p. 83

- ↑ Email from George Melvin, Maine, via Bill Linley (31 May 2020) noting that apples were shipped from the Annapolis Valley to processors in upstate NY in reefers of the Rutland Ogdensburg Line in the early 1950s.